Cassava ethanol is reshaping biofuel conversations. This guide introduces what it is, how it’s made, and why it’s gaining ground in energy, agriculture, and industrial production worldwide.

Cassava ethanol cannot be ignored in the global shift toward cleaner energy.

You’re seeing it mentioned in energy plans, agricultural policies, and investment proposals.

But what makes it so relevant right now? This guide gives you a clear view.

You’ll walk through how the cassava root is turned into ethanol, what’s involved in setting up a plant, and where the real costs come in.

From farming to fermentation, every step matters if you’re aiming for efficiency and long-term value.

Countries with access to cassava are already seeing how it can support rural jobs, reduce fuel imports, and contribute to local energy security.

If you’re thinking about producing, investing, or just understanding the process better, this page sets the stage.

Cassava ethanol bridges the gap between agriculture and energy in ways that are practical, scalable, and timely.

Recommended: Cassava Business Plan Examples

What is Cassava Ethanol?

Cassava ethanol is a biofuel made from the starchy roots of the cassava plant.

Grown widely in tropical regions, cassava serves as an efficient feedstock for ethanol due to its high starch yield and ability to grow in less fertile soils.

The process starts by converting the cassava starch into fermentable sugars, then fermenting those sugars with yeast to produce ethanol.

Technologies like enzymatic conversion and dry milling help improve efficiency and output.

Cassava ethanol can be refined for use in fuel, industrial solvents, and even household energy.

Its growing appeal lies in its role as a cleaner energy source that supports rural development, reduces dependence on fossil fuels, and turns local crops into sustainable power and economic growth.

Related: How to Peel Cassava the Right Way

Why Cassava is Ideal for Ethanol Production

You may not think of cassava as your go-to energy crop, but it quietly outperforms many traditional sources used for ethanol.

Here’s why it deserves your attention:

High starch content means more ethanol from less crop

Cassava roots are packed with starch, up to 30 percent of their weight.

This starch is broken down into fermentable sugars for ethanol production.

The more starch you have, the more fuel you can make.

Unlike crops that produce less sugar per hectare, cassava gives you a higher ethanol yield without needing extra land or effort.

Fast growth gives quicker returns

You don’t need to wait forever to harvest. Cassava matures in as little as six months, making it one of the quickest-growing crops for ethanol.

This short growth cycle lets you plant and harvest more frequently, which translates into faster income for farmers and quicker production cycles for ethanol plants.

Grows where other crops struggle

Cassava doesn’t demand rich soil. It can thrive in dry, degraded, or nutrient-poor land that wouldn’t support most food crops.

This means you can use land that’s otherwise left idle. By doing so, you help prevent competition with food farming while still tapping into biofuel production.

Needs less water than corn and sugarcane

Water is a big deal in agriculture. Cassava needs much less irrigation than sugarcane or corn, making it a smart choice in dry regions.

This lower water demand reduces strain on limited water resources and keeps input costs manageable, which benefits both farmers and the environment. See more on the climatic conditions for cassava.

Fits into sustainable energy plans

Cassava supports your clean energy goals without adding to food scarcity or exhausting natural resources.

It’s efficient, resilient, and better suited for long-term use than many alternatives.

When you invest in cassava for ethanol, you’re backing a crop that supports both energy and environmental stability.

Related Posts

- Modern Methods of Processing Cassava

- Cassava Processing Equipment Guide

- Traditional Ways of Cassava Processing

- How to Process Garri (Cassava Flakes)

- How To Process Cassava With One Machine

- Insights on Commercial Cassava Flour Production

Environmental and Economic Benefits of Cassava Bioethanol

If you’re looking for a fuel source that supports both your business and the planet, cassava bioethanol gives you strong reasons to pay attention.

Here’s why:

Cuts down greenhouse gas emissions

Cassava bioethanol can help reduce carbon emissions by replacing fossil fuels.

Since cassava absorbs carbon dioxide during growth, its use as biofuel supports a closed carbon loop.

When you use ethanol made from cassava, you release fewer pollutants into the air.

That’s better for your environment, and it puts your project in line with clean energy targets.

Reduces fuel imports and strengthens local supply

Producing ethanol from cassava gives your country more control over its fuel supply.

Instead of spending money on imported fuels, you invest in local crops and jobs.

This strengthens the local economy and improves energy security.

It also helps balance trade deficits and creates market opportunities for farmers and processing businesses.

Adds value to agricultural waste

Cassava peels, pulp, and leaves don’t have to go to waste. You can turn them into animal feed, compost, or energy.

By using every part of the plant, you reduce disposal costs and open new income streams.

This supports a circular economy model and makes your ethanol plant more efficient.

Creates rural jobs and supports farming communities

Cassava bioethanol creates steady work in planting, harvesting, transport, and cassava processing.

If you’re building in a rural area, your project can lift local incomes and strengthen food and energy systems.

Farmers get a reliable market, and processing plants create year-round employment.

The result is a stronger rural economy with more long-term opportunities.

How to Produce Cassava Ethanol: A Step-by-Step Guide

Cassava ethanol is made through a process that transforms fresh tubers into clean-burning fuel.

You’ll move from root preparation to final storage through a series of connected stages. Here’s your full breakdown:

- Step 1: Cassava Sourcing and Quality Preparation

- Step 2: Washing, Peeling, and Chipping Cassava

- Step 3: Turning Cassava Starch into Fermentable Sugars

- Step 4: Fermentation Phase in Cassava Ethanol Production

- Step 5: Distillation in Cassava Ethanol Production

- Step 6: Dehydration and Purification in Cassava Ethanol Production

- Step 7: Storage and Packaging in Cassava Ethanol Production

Let’s take a closer look at each step:

Step 1: Cassava Sourcing and Quality Preparation

Cassava ethanol production begins with selecting and preparing high-quality cassava tubers.

You need varieties with high starch content, like Manihot esculenta or TMS 30572, to ensure better ethanol yield.

Freshness matters; tubers should be free from rot and have a moisture content of 60 to 70 percent.

Starch levels should ideally exceed 25 percent for efficient sugar conversion. Harvesting at 10 to 12 months gives the best starch concentration.

Sorting and removing defective tubers is key.

Getting this step right sets the foundation for a smooth fermentation process and increases overall ethanol output.

Quality sourcing always pays off down the line.

Step 2: Washing, Peeling, and Chipping Cassava

Before you get to fermentation, how you handle your cassava makes a big difference.

- Washing: Washing, peeling, and chipping are more than just prep steps; they directly shape your ethanol yield and process flow.

- Cleaning: Start by cleaning the roots thoroughly. Use clean water and agitate them gently in a tank to remove soil and microbes. A second rinse helps flush out anything left behind. Keep your tools and tanks clean, too. A dirty wash setup can cause trouble down the line.

- Peeling: Peeling comes next. You can do this by hand or with machines, but always aim to remove the skin cleanly without wasting the starchy core. That’s where the fuel is. Use sanitized tools if you’re peeling by hand to maintain a hygienic process. See how to peel a cassava root the right way.

- Chipping: Once peeled, slice the cassava into chips. Keep the sizes uniform. If your chips are too big or uneven, fermentation slows down. Balanced chips give yeast more surface to work with, helping you turn more starch into ethanol. Clean handling now saves you time and cost later.

Step 3: Turning Cassava Starch into Fermentable Sugars

You’re now at the stage where cassava starts turning into fuel. Starch extraction and hydrolysis are key steps that prepare cassava for fermentation and ethanol production.

Create the mash for starch release

After cleaning, peeling, and grating your cassava, you’re left with a soft mash. This mash needs to be soaked in water, then pressed or centrifuged.

Your goal is to pull out the starch while leaving behind fiber.

This step gives you a starch-rich base that gets broken down into sugars in the next stage.

Break down starch with enzyme hydrolysis

Starch is not fermentable as it is, so you need to break it into sugars. You’ll use enzymes like α-amylase and glucoamylase.

The first cracks open long chains of starch into smaller units. The second finishes the job by turning them into glucose.

This step is what makes cassava ready to become ethanol.

Keep your temperature and pH in check

Your enzymes need the right working conditions. If it’s too hot or too acidic, they slow down or stop working.

Keep the temperature steady and adjust the pH to suit each enzyme. This small step can make a big difference in how much sugar you get from your starch.

Maximize your sugar yield for better ethanol output

Everything you do here, grating the cassava well, separating starch cleanly, managing your enzymes, affects how much sugar you end up with.

The more sugar you make, the more ethanol you can produce later.

Getting it right at this stage sets you up for higher efficiency and less waste during fermentation.

Step 4: Fermentation Phase in Cassava Ethanol Processing

This is where cassava mash becomes ethanol. You’ll guide sugars into becoming fuel by creating the right conditions for yeast to work.

Let’s break it down clearly:

Yeast Strains: Choosing the Right Worker

You’ll rely on yeast to do the conversion. Saccharomyces cerevisiae is your go-to strain.

It’s reliable under low oxygen and keeps producing even as alcohol levels rise.

Some producers also try Kluyveromyces marxianus, especially when lactose is involved. Your choice depends on the sugar type and your setup.

Good yeast equals better yield, so don’t overlook this step.

Temperature Control: Keeping It Just Right

Stick to 25 to 30 degrees Celsius during fermentation.

Yeast works best in this range. If it gets too hot, yeast slows down or dies. Too cold, and the process drags.

Use insulated vessels or water baths to keep it steady. Think of it like cooking: get the heat right, and everything flows smoothly.

pH Level: Keeping Conditions Favorable

Keep the pH between 4.5 and 5.5. Yeast prefers this slightly acidic range. When pH drops too low or climbs too high, yeast gets stressed and slows down.

Check pH regularly and adjust with food-grade buffers. If you ignore this, expect weak yields and sluggish fermentation. Small tweaks here go a long way.

Fermentation Time: Watching the Clock

Let the mash ferment for 24 to 72 hours. The exact time depends on your yeast, temperature, and sugar levels.

Monitor progress by checking sugar concentration or how much ethanol you’re getting. Don’t rush it.

Let the yeast finish its job before moving on. A rushed batch might mean wasted starch and lower returns.

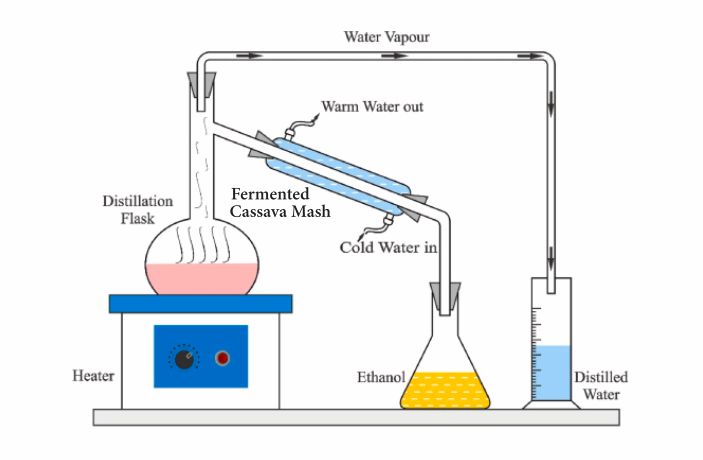

Step 5: Distillation in Cassava Ethanol Production

Now that fermentation is complete, your focus shifts to separating ethanol from the rest of the mixture.

Distillation lets you collect cleaner, stronger ethanol. Here’s how it works:

Heating the Mash: Starting the Separation

Once fermentation is done, you’ll heat the fermented cassava mash. Ethanol has a lower boiling point than water, so it turns to vapor first.

As the mash heats up, ethanol rises while water and leftovers stay behind.

This phase needs care. If the heat goes too high, you’ll lose ethanol or scorch the mash.

A steady heat lets ethanol vaporize cleanly and prepares it for collection.

Condensing the Vapor: Turning Gas into Liquid

After vaporization, ethanol moves into a condenser. Here, it cools down and becomes liquid again.

This liquid is your first round of distilled ethanol. At this point, it’s still not pure. But you’ve already boosted its concentration.

Proper condensation is key. If the cooling isn’t done right, vapor can escape, and that’s lost product. Keep it sealed and steady.

Multiple Cycles: Boosting Purity Levels

Your first distillation gives you low-purity ethanol, usually around 50 to 60 percent.

To go higher, you’ll run it through more cycles. Each pass removes more water and improves ethanol strength.

This is how you reach the levels needed for fuel or industry. Keep in mind, each cycle takes time and energy. So, balance effort and output.

Fuel-Grade Ethanol: For Clean Energy Use

After a few rounds of distillation, you’ll reach fuel-grade quality. This is about 94 percent pure.

At this level, ethanol can be used as a renewable fuel or mixed with gasoline.

It meets clean energy goals and cuts down on fossil fuel reliance. If your goal is biofuel, this is where you stop.

Store it properly, and it’s ready to go.

Industrial-Grade Ethanol: For Broader Applications

If you keep refining, you can reach 99 percent purity or more. This ultra-clean ethanol is for industrial uses.

It goes into solvents, food processing, and even medicines. Regulations get stricter here, so keep your process clean and traceable.

The more refined the product, the higher the standards you’ll need to meet. But the payoff is also better if done right.

Step 6: Dehydration and Purification in Cassava Ethanol Processing

At this point, you’ve distilled your ethanol, but it still contains water. To make it purer, especially for fuel or industrial use, you’ll now dehydrate and purify it.

Using Molecular Sieves: Trapping Water, Keeping Ethanol

Molecular sieves help you pull out the last bit of water from your ethanol. These tiny solids have pores that catch water but let ethanol pass.

Think of it like a filter with super small holes. Once full, you can heat the sieve to release the water and use it again.

This makes the method efficient and cost-friendly. It’s a common choice in cassava-based ethanol setups because it works well and doesn’t need too much energy.

Membrane Separation: Filtering with Precision

Membrane separation is another way to get pure ethanol. Here, you use special membranes to split ethanol from water.

The membrane acts like a smart barrier, allowing only ethanol or water to move through, depending on the setup.

This technique uses less heat, so it saves energy. You can use pressure-based systems like reverse osmosis or more advanced membranes designed for alcohol separation.

It’s useful when you want high-purity ethanol for strict industrial or energy standards.

Step 7: Storage and Packaging in Cassava Ethanol Production

Now that your cassava ethanol is purified, it’s time to store and package it safely. This stage keeps the product stable, safe, and ready for transport or sale.

Choosing the Right Storage Tanks: Protecting the Product

You need tanks that can handle ethanol without corroding or leaking. Stainless steel and certain carbon steels are good choices.

They last longer and don’t react with ethanol.

Think about the tank’s size, ventilation, and location. Keep tanks away from heat or open flames, and install fire control systems.

This helps reduce risks and keeps your product secure over time.

Meeting Storage Rules: Staying Compliant and Safe

Don’t overlook legal requirements. Ethanol storage is strictly regulated. You’ll need tanks that follow approved standards, with regular inspections and documented maintenance.

Local laws also guide where and how you place your tanks. Skipping these steps can cost you fines or worse, safety issues. Keep records, run safety drills, and check for leaks regularly to stay ahead of any problems.

Smart Packaging: Securing Ethanol for Transport

When it’s time to move your ethanol, packaging matters. Use containers that don’t leak and can handle the trip.

Drums, jerrycans, or bulk containers should meet safety codes. Always include clear labels with hazard warnings and handling instructions.

Proper sealing avoids spills and shows that you’re handling your product responsibly.

It also gives transporters and buyers the details they need to use it safely.

Setting Up a Cassava Ethanol Production Plant and Having it Running

Starting a cassava ethanol plant is more than putting machines in place. You’ll need the right scale, tools, infrastructure, and supply chain to make your operation work from the ground up.

Plant Size and Output Capacity

Before anything else, you need to define your plant’s scale. Are you producing for a local community or aiming for the commercial fuel market?

A small-scale cassava ethanol plant can produce 100 to 1,000 liters daily, ideal if you’re serving a niche market or testing the waters.

With less financial pressure and flexibility in sourcing cassava, it’s easier to manage.

For a commercial setup, expect to handle over 10,000 liters per day.

This requires consistent cassava supply, strong funding, and reliable processing systems.

Choose your size based on raw material access, your budget, and long-term goals.

Equipment Needed

You’ll need a chain of reliable machines to get from raw cassava to pure ethanol.

- Grater: Start with a grater, it breaks down the roots for starch release. Finer grating gives you better results during fermentation.

- Hydrocyclone: Then comes the hydrocyclone, which removes fibers from your starch slurry using centrifugal force.

- Fermentation tank: A fermentation tank follows, where yeast converts sugars to ethanol under controlled conditions.

- Distillation unit: You’ll also need a distillation unit to purify the ethanol, separating it from water and residues.

- Boiler: A boiler keeps everything running by supplying the steam needed for distillation and heating.

Choosing the right equipment affects efficiency, output, and how much you’ll spend daily.

Land and Infrastructure Requirements

Your plant needs the right space to run smoothly. Think beyond just fitting your machines; you also need room for cassava storage, wastewater treatment, and worker facilities.

Choose land near cassava farms to cut down on transport costs and avoid delays.

You’ll also need reliable electricity and clean water since both are heavily used in ethanol production.

Consider backup energy like solar or biogas to control long-term costs.

Plan waste management from the start with a system for solid waste and water discharge.

Infrastructure choices now will decide how efficiently and sustainably your plant runs tomorrow.

Regulatory and Safety Compliance (in the U.S.)

If you’re setting up your plant in the U.S., you’ll need to meet several legal and safety rules.

The Environmental Protection Agency (EPA) checks how well your plant handles emissions and wastewater.

Make sure you get permits, keep records, and monitor your impact.

You also need to follow Occupational Safety and Health Administration (OSHA) rules that cover worker safety, from using chemicals to handling machinery.

Your ethanol must meet Renewable Fuel Standard (RFS) targets if you want access to tax credits or blending programs.

Staying compliant protects your investment, keeps your team safe, and helps you access the fuel market legally.

Market Analysis and Economic Feasibility

Understanding your market can help you avoid costly mistakes.

Global demand for biofuels is growing, driven by clean energy goals and fuel blend mandates.

Cassava offers a cheaper feedstock than corn or sugarcane, especially in areas where it’s locally grown.

Still, prices can shift based on farming output, transport costs, and climate.

You need to run numbers: how much ethanol will each ton of cassava give you, and what’s your break-even price?

Keep an eye on policies in your target region. Government incentives or mandates for ethanol blends can shape your business success.

A solid financial plan is your safety net.

Sourcing Raw Materials

Your entire production line depends on cassava, so securing a reliable supply is a must.

Work with farmers through contracts that promise fair prices and steady demand.

Train them on high-yield, eco-friendly farming methods to protect soil and ensure consistent harvests.

If you’re growing your own, invest in good seed varieties and land preparation.

Don’t forget logistics, fresh cassava spoils fast. Set up a smooth system for harvesting, transporting, and storing it before processing.

With the right network and planning, you can avoid gaps in production and maintain steady ethanol output throughout the year.

Technology and Innovation in Cassava Ethanol Production

When you’re producing ethanol from cassava, new technology has made the work faster, cleaner, and smarter.

You’re no longer stuck with outdated systems that waste energy or resources.

Smarter Fermentation with Fewer Steps

You can now combine starch breakdown and fermentation in one step using consolidated bioprocessing.

Instead of managing two separate stages, this method lets enzymes and microbes work together in the same tank.

That means less equipment, lower energy use, and faster results.

It’s a simpler way to get more ethanol out of your cassava mash without increasing your operating costs.

Enzymes That Work Harder and Faster

Modern enzymes are built to break cassava starch down better.

With thermostable amylases, you’re able to run the process at higher temperatures, which speeds things up and boosts efficiency.

These enzymes help convert more starch into sugar, and that sugar turns into more ethanol.

You don’t need to use more cassava, just smarter enzymes to get better results.

Automation That Thinks for You

With automated monitoring tools, you’re in control of everything without being everywhere.

Sensors and smart controls keep track of temperature, pH, and fermentation rates around the clock.

You get real-time updates and alerts, so you can fix problems before they grow.

This kind of automation lowers labor costs, reduces waste, and improves safety across the board.

Better Bioreactors for Higher Output

Today’s bioreactors come with better mixing and temperature control.

This gives your yeast the ideal environment to turn sugars into ethanol without delays or drop-offs in performance.

When your yeast works better, your ethanol output goes up.

Upgrading to advanced bioreactors is one of the fastest ways to get more from the same amount of cassava.

Cassava Ethanol Production Costs

If you’re thinking about producing ethanol from cassava, knowing where your money goes is the first step. It helps you plan better and avoid surprises.

Capital Investment: What You Need to Start

Starting a cassava ethanol plant takes more than just an idea. You’ll need to buy land, build a facility, and install machines like fermenters and distillers.

The location you choose affects land price, access to cassava, and transport. You’ll also spend on permits and basic infrastructure.

Plan carefully so you don’t run into delays or unexpected costs that could throw off your budget.

Operating Costs: What It Takes to Run

Running the plant means paying for labor, cassava feedstock, enzymes, water, and electricity.

Labor can be a major cost depending on local wages. The price of cassava changes with season and supply, so having good supplier relationships helps.

Enzymes break down starch into sugar, which is key to producing ethanol.

Water and power are also big parts of your monthly expenses, so energy-saving measures are worth considering.

Cost Per Liter of Ethanol: What You Pay to Produce

The cost to make one liter of cassava ethanol depends on your location, production size, and process efficiency.

Small plants usually pay more per liter because they buy inputs in smaller quantities.

Larger operations can spread their costs across more output.

If your plant is near cassava farms and has access to stable power and labor, your cost per liter will likely be lower.

Scale and smart logistics can make a big difference.

Comparing Cassava with Other Feedstocks

Cassava competes well against feedstocks like corn and sugarcane. It needs fewer chemical inputs and grows in poor soil.

Cassava can yield more starch per hectare than corn and is less water-hungry than sugarcane.

While sugarcane may produce more ethanol per hectare, cassava’s lower farming costs and resilience make it attractive.

If sustainability and adaptability matter in your region, cassava is a smart option to consider.

Economic Feasibility and ROI: Is It Worth It?

You want to know when your investment will pay off. That depends on how much you spend to set up, how efficiently you run the plant, and what price you get for ethanol.

Calculate the return on investment by weighing your startup costs against expected profits.

Look at local and international demand, current ethanol prices, and any incentives.

The faster you recover your setup costs, the sooner you start earning real profit.

Profitability Factors: What Drives Your Earnings

Market demand for biofuels plays a big role. Rising interest in renewable energy means more buyers for cassava ethanol.

Government support, like tax breaks and grants, can improve your margins. Oil prices also matter.

When fossil fuels get expensive, biofuels look more attractive. Technology can help, too.

Better machines and smarter processing reduce waste and increase output. Keep an eye on trends so you can stay ahead of market shifts.

Opportunities for Cassava Ethanol in the U.S. Market

Cassava ethanol is catching attention in the U.S. as a cleaner fuel source.

With shifting energy needs and new policies in place, you have real opportunities to watch and act on.

Demand for clean fuels

You’re seeing more pressure than ever for low-emission fuel options.

As industries move toward decarbonization, cassava ethanol gives you a plant-based fuel that meets cleaner energy goals.

U.S. refiners and transportation sectors are looking for ethanol sources that go beyond corn.

Cassava’s high starch yield makes it a strong alternative, especially when processed efficiently.

If you’re in agriculture, logistics, or energy, the growing push for clean fuel creates space for cassava ethanol to fit into the supply chain.

Policy support for renewable energy

Federal and state incentives are pushing renewable fuel production.

Programs like the Renewable Fuel Standard (RFS) give you credits for blending bioethanol into gasoline.

Cassava ethanol can meet these requirements if it meets lifecycle greenhouse gas thresholds.

California’s Low Carbon Fuel Standard (LCFS) also rewards fuels with lower carbon intensity.

These rules are pushing energy producers to diversify ethanol sources.

If you’re a policy-aware entrepreneur or investor, cassava ethanol stands out as a feedstock that can compete with traditional grains under these guidelines.

Import potential from Africa and Asia

Countries like Nigeria, Thailand, and Indonesia grow cassava on a large scale and are building processing plants to export ethanol.

With the U.S. increasing its clean energy demand, cassava ethanol imports could fill gaps in supply.

If you’re in the import-export business, this opens doors.

Trade agreements and lower production costs in tropical regions can make cassava ethanol a price-competitive option.

Establishing reliable supply chains between these regions and U.S. ports could strengthen availability and reduce pressure on domestic ethanol sources.

U.S. companies investing in bioethanol diversification

More companies are looking beyond corn to avoid price fluctuations and crop limitations.

Some U.S. firms are researching cassava as part of their ethanol mix, especially for long-term energy security.

If you’re a startup or part of a research institute, there’s room to contribute to pilot programs or collaborate with international growers.

Cassava ethanol can be part of a broader portfolio that includes cellulosic and algae-based ethanol.

With the right processing tech and strategic partnerships, you can help drive the shift to new bioethanol pathways.

Environmental and Sustainability Considerations

Cassava ethanol brings cleaner energy into the picture, but it’s important to look at how it affects the environment and what you can do to keep production sustainable.

Lower greenhouse gas emissions from renewable feedstock

Cassava ethanol can help cut greenhouse gas emissions by up to 80 percent when compared to fossil fuels.

Since cassava plants absorb carbon dioxide as they grow, they form part of a balanced carbon cycle.

That makes cassava a strong alternative energy source, but you still need to look at the full life cycle, from farming practices to processing, to understand the complete environmental impact.

Repurpose by-products and support a circular economy

You don’t have to waste anything. Cassava peels, leaves, and leftover pulp can be turned into animal feed, fertilizer, or biogas.

This helps you reduce waste and get more value from every part of the crop.

Using these by-products wisely makes your ethanol plant more efficient and less harmful to the environment.

Balance land use to protect food security

If you’re working in areas where cassava is a food staple, you need to consider who else depends on the crop.

Growing cassava for fuel could limit access to food. To avoid this, set up practices that prioritize food needs while still supporting clean fuel production.

The goal is to grow energy without taking meals off the table.

Challenges in Cassava Ethanol Development

If you’re considering cassava ethanol production, there are real challenges you need to work through.

Knowing them upfront helps you plan better and build a stronger project.

Cassava spoils fast after harvest

Cassava roots start spoiling within a few days after harvest. Without quick processing, you lose both yield and quality.

Timely harvesting, transportation, and processing are necessary to prevent losses and maintain profitability in ethanol production.

Seasonal Availability and Shelf-Life of Cassava

Cassava is seasonal and spoils fast, which limits how far and when you can process it.

You’ll need reliable planning, storage solutions, or supplier contracts to maintain a steady year-round supply without sacrificing raw material quality.

Cost of Enzymes and Fermentation Optimization

Enzymes are vital but costly. Without proper fermentation conditions, the right temperature, pH, and mixing, you risk wasting money and reducing output.

Skilled workers and close monitoring are key to improving efficiency and getting the most from every batch.

Waste Management: Stillage Disposal

Stillage is a wet, bulky byproduct that needs proper handling. Dumping it isn’t an option, and drying it takes energy.

Without a waste management plan, you risk extra costs and regulatory problems that can hurt your operation.

Logistics for Export and Import

Exporting ethanol and importing supplies requires dependable logistics. Poor roads, port delays, or high shipping costs can affect profits.

To stay competitive, you’ll need strong supply chains and local infrastructure that support smooth, timely operations.

Price swings make long-term planning hard

Cassava prices are unstable, affected by demand, weather, and competing crops.

That volatility makes it hard to forecast costs and attract investment. Managing those price risks is necessary to keep your business steady and profitable.

Weak infrastructure slows production

Bad roads, limited storage, and few processing plants slow production and raise costs.

You may need to invest in your infrastructure or form partnerships to fill those gaps and keep your supply chain running smoothly.

Unclear policies create business risk

Lack of clear biofuel policies creates uncertainty. Without defined support or regulation, it’s hard to secure funding or plan long-term.

Staying updated and flexible is your best defense until stronger policies are in place.

Future of Cassava Ethanol

If you’re looking ahead, cassava ethanol gives you a lot to think about.

Research and local energy models are setting the stage for real progress in how this fuel is produced and used.

Better cassava varieties boost starch yields

Researchers are working on new cassava breeds with more starch per root. That means you can get more ethanol without planting more land.

Higher starch content improves processing efficiency and helps cut costs.

These improvements can make cassava more attractive to both farmers and ethanol producers, giving you better returns on your investment.

Local energy systems reduce dependence

Decentralized energy setups let you produce cassava ethanol closer to where it’s needed.

That cuts transport costs and makes rural communities more energy independent.

When small processing units are placed near farms, they also create jobs and support local economies.

This kind of setup brings more stability to the supply chain and strengthens energy access in remote areas.

Cassava ethanol supports a greener economy

Switching to cassava ethanol helps cut greenhouse gas emissions.

As a renewable fuel, it reduces your reliance on fossil energy and supports the shift to cleaner energy sources.

On top of that, cassava farming creates rural jobs and encourages land use that supports biodiversity.

It’s a win for both your community and the climate.

Innovation and local action shape long-term impact

The future of cassava ethanol depends on how you invest in research and apply smart technology.

By supporting improved farming practices, better processing tools, and policies that back clean energy, you’re helping build a stronger, more reliable fuel system.

With the right support, cassava ethanol has the power to lead real change in renewable energy.

Frequently Asked Questions about Cassava Ethanol

What makes cassava a good choice for ethanol production

Cassava’s high starch content, low input needs, and ability to grow in poor soil make it cost-effective for ethanol, supporting steady yields with minimal land and water use.

How does cassava ethanol benefit the environment?

Cassava ethanol cuts greenhouse gas emissions by up to 80 percent, reuses waste, and supports better land use, making it a cleaner energy source when produced responsibly.

What are the main steps in cassava ethanol production?

Ethanol production from cassava involves washing, chipping, starch hydrolysis, fermentation, distillation, dehydration, and safe storage, ensuring clean fuel from farm to final tank.

What challenges does cassava ethanol production face

Short shelf life, seasonal limits, enzyme costs, poor infrastructure, and waste pollution pose barriers to cassava ethanol and require careful planning to manage.

How can cassava ethanol support rural communities

Cassava ethanol boosts rural jobs, gives farmers steady income, and brings decentralized energy closer to villages, helping local economies grow over time.

Is cassava ethanol production environmentally friendly?

Yes, when managed well. Cassava absorbs carbon dioxide and produces fewer emissions, and by-products can be reused to reduce waste.

Conclusion

Cassava ethanol is a promising biofuel that bridges agriculture and clean energy, offering a sustainable path for global energy needs.

Its high starch yield, resilience in poor soils, and low water requirements make it a practical alternative to traditional feedstocks like corn and sugarcane.

By reducing greenhouse gas emissions, repurposing waste, and creating rural jobs, it supports both environmental and economic goals.

Despite challenges like spoilage, seasonal supply, and infrastructure gaps, innovations in fermentation, enzymes, and automation are driving efficiency and scalability.

With supportive policies and continued research, cassava ethanol can play a key role in a greener economy, empowering communities and reducing reliance on fossil fuels.

References

- Single-step ethanol production from raw cassava starch

- Production Of Edible Ethanol 95.5% Alcohol From Cassava

- Enzymatic Production of Ethanol from Cassava Starch

Chimeremeze Emeh is a writer and researcher passionate about Africa’s most transformative root crop—cassava. Through his work at cassavavaluechain.com, he explores the entire cassava industry, from cultivation and processing to its diverse applications in food, health, and industrial use.

He also writes for palmoilpalm.com, where he shares his extensive experience and deep-rooted knowledge of palm oil, covering red palm oil, palm kernel oil, and refined products. His work there reflects his lifelong connection to agriculture and his commitment to promoting sustainable value chains in Africa.

Driven by curiosity and purpose, Chimeremeze aims to shed light on how cassava continues to empower communities, strengthen food systems, and link traditional farming wisdom with modern innovation.