Cassava processing makes cassava products safe by removing toxins and transforming the raw root into flour, starch, chips, pellets, and biofuel. Explore methods, challenges, and innovations for safety, efficiency, and sustainability!

Cassava processing is an important step to unlocking the full potential of this supercrop.

Fresh cassava root is highly perishable, making processing essential for preservation, extended shelf life, reduced food waste, and other by-products.

Techniques such as drying, fermentation, and milling not only prevent spoilage but also enhance the nutritional profile and sensory qualities of cassava, making it more palatable and marketable.

Beyond cassava farming for food production, cassava processing plays a chief role in industrial applications.

Cassava starch is a key ingredient in food, pharmaceuticals, paper, and textile industries, while cassava peels and fiber serve as sustainable animal feed.

This guide explores both traditional and modern processing techniques, comparing their efficiency, economic impact, and sustainability to provide a complete understanding of cassava processing.

Recommended: Step-by-step Guide to Cassava Ethanol Production

What is Cassava Processing?

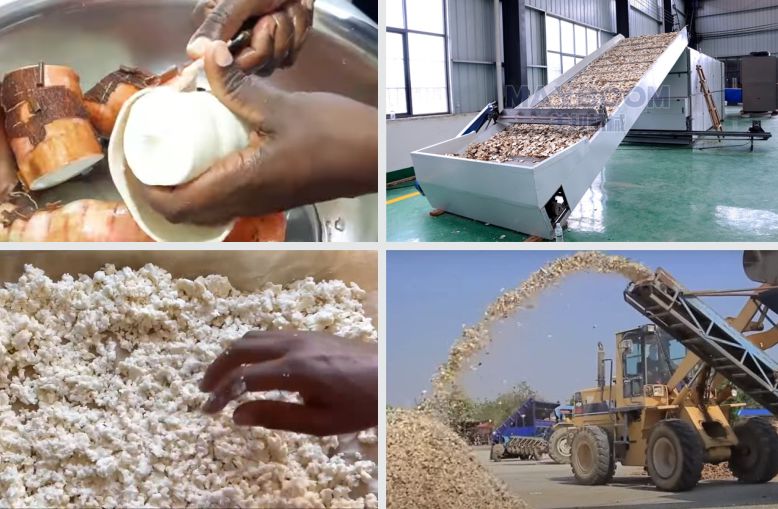

Cassava processing involves various methods to transform fresh cassava roots into different products, such as fried chips, flour, and starch. Traditional methods include peeling, grating, and fermentation, while modern methods incorporate advanced technologies like mechanical peeling and extrusion to improve efficiency and product quality.

Why Cassava Needs Processing

Processing cassava removes or reduces the potentially toxic cyanogenic glucosides present in fresh cassava, making it safe for consumption. It is also necessary for preservation and value addition.

Without proper treatment, fresh cassava spoils quickly and contains toxic compounds that can be harmful if consumed in large quantities.

Processing not only removes these toxins but also improves shelf life, taste, and usability in various industries.

Removing Natural Toxins

Raw cassava contains cyanogenic glycosides, which release hydrogen cyanide when broken down.

Ingesting large amounts of unprocessed cassava can cause cyanide poisoning, leading to symptoms like dizziness, headaches, and, in severe cases, neurological damage.

Methods such as soaking, fermenting, drying, and boiling significantly reduce these toxins, making cassava safe for consumption. More on how to remove cyanide from cassava.

Extending Shelf Life and Reducing Waste

Cassava has a high moisture content, making it highly perishable. Within 24 to 72 hours after harvest, it begins to deteriorate, leading to losses if not processed in time.

Drying, milling, or fermenting converts cassava into more stable forms like flour, starch, and chips, which can last for months without spoiling.

Preserving Nutrients

While cassava is rich in carbohydrates, improper processing can strip it of beneficial nutrients.

Controlled fermentation and drying techniques help retain essential vitamins and minerals, such as vitamin C, fiber, and iron.

Fermentation also enhances its digestibility by breaking down anti-nutrients that interfere with absorption.

Improving Taste and Texture

Raw cassava has a bland or bitter taste due to its natural compounds.

Processing enhances its flavor, removes bitterness, and makes it suitable for different culinary and industrial applications.

Properly processed cassava is used in making everything from flour and starch to tapioca and animal feed.

Related: Multi-Function Cassava Machines For Small Businesses

Expanding Industrial and Commercial Uses

Beyond food, cassava processing plays a key role in industries like textiles, adhesives, and biofuels.

Cassava starch is widely used in paper manufacturing, pharmaceuticals, and biodegradable plastics.

Processing transforms cassava into valuable raw materials that contribute to economic growth and sustainable production.

Without proper processing, cassava’s potential is wasted. Whether for home use, commercial production, or industrial applications, turning raw cassava into safe, long-lasting, and versatile products ensures both safety and economic benefits.

Related Posts

Cassava Processing Equipment Guide

Guide to Cassava Chipper Machine

Cassava Cuisines Around the World

Some Investment Opportunities in the Cassava Industry

How to Profit from the Cassava Value Chain

Different Names for Cassava around the World

Cyanide Poisoning from Cassava: Symptoms, Treatment and Prevention

How to choose the right cassava sieving machine for your processing scale

Cassava Processing in the Cassava Value Chain

Cassava processing is a pivotal step in the cassava value chain, transforming raw roots into valuable products like flour, starch, chips, pellets, and biofuel.

These processed products serve diverse industries, from food production to pharmaceuticals and biofuels, enhancing food security, nutrition, and sustainability.

The process removes harmful toxins like cyanogenic glycosides, ensuring safety and increasing shelf life.

Efficient processing reduces waste and maximizes the economic potential of cassava.

Innovations in processing technology, along with sustainable practices, help improve productivity and quality, benefiting both smallholder farmers and large-scale industries.

By adding value to cassava, the processing stage strengthens its position as a key agricultural and industrial resource, supporting global markets and contributing to renewable energy initiatives.

Related: Guide to Tapioca: Everything to Know

Cassava Processing Methods

Cassava processing methods transform raw cassava roots into various food and industrial products, improving shelf life, safety, and usability.

These methods are broadly categorized into traditional and modern techniques.

Traditional methods rely on manual labor, including peeling, chipping, grating, soaking, and fermentation to produce staple foods like gari, fufu, and flour.

They also use sun-drying, boiling, and roasting for preservation and consumption.

In contrast, modern processing employs industrial machinery for efficiency, such as automated peeling, high-tech milling, flash drying, and mechanized starch extraction.

Advanced methods like hydrothermal treatment and bioethanol production maximize cassava’s industrial potential.

Understanding these techniques is crucial for optimizing cassava use in food security, commercial production, and sustainability efforts.

Related: Managing the Cassava Glut Season

Traditional Processing Methods of Cassava

Cassava is a staple crop in tropical regions, processed traditionally through peeling, grating, fermenting, drying, and smoking.

These methods improve flavor, safety, and shelf life. Peeling removes harmful compounds, while grating increases surface area for fermentation, a crucial step in producing foods like gari and fufu.

Sun-drying reduces moisture for long-term storage, and smoking enhances taste while preventing spoilage.

Different regions have unique techniques:

- West Africa ferments cassava for various dishes,

- Brazil produces tucupi from its juice, and

- Southeast Asia turns it into flour and starch.

These time-honored methods preserve food security and cultural heritage, ensuring cassava remains a vital resource for many communities worldwide.

Here are the processes of the traditional cassava processing methods:

- Harvesting: Traditional methods of cassava harvesting have deep historical roots and are tied to the cultural practices of various communities where it is cultivated.

- Peeling: There is, however, a semi-mechanized cassava processing technique by Noal Farm. Removes cassava’s tough outer skin to eliminate toxins and prepare the root for further processing.

- Boiling: Boiling cassava involves peeling, cutting, and immersing the roots in boiling water. It reduces cyanide content, softens the texture, and prepares cassava for consumption or further processing into meals.

- Grating: Turn peeled cassava into a fine pulp, increasing surface area for fermentation and further preparation.

- Fermentation: Enhances flavor, removes toxins, and improves shelf life by allowing beneficial bacteria to break down starches.

- Sun-Drying: Dries cassava under the sun to reduce moisture content and extend storage time without refrigeration.

- Smoking: Adds a distinct flavor while preventing mold, spoilage, and pest infestation for long-term preservation.

- Starch and Flour Extraction: Traditional cassava starch and flour extraction involves peeling, washing, and crushing roots into pulp. Starch granules are separated via filtration, sedimentation, and drying. Flour production includes grinding dried pulp

See a dedicated article on the traditional methods of processing cassava.

Modern Cassava Processing Techniques

There have been breakthroughs in the manufacture of tailored equipment for the processing of cassava for efficiency and cost-effectiveness, strengthening and commercializing the cassava value chain, and the economic value of the crop.

The modern processing of cassava follows the same steps as described in the traditional methods above. The only difference is that in modern methods, it is mechanized.

Mechanized peeling reduces labor while minimizing waste, ensuring higher yields.

Chipping machines slice cassava into uniform pieces, facilitating consistent drying and milling for better flour and starch production.

Advanced milling techniques refine cassava into finer particles, improving its functionality in various applications.

Industrial drying methods, such as solar and drum drying, extend shelf life by reducing moisture content, while fermentation enhances nutritional value, making cassava products suitable for gluten-free diets.

Modern starch extraction utilizes centrifuges and filtration, increasing yield and purity for food and industrial use.

Chemical processing and enzymatic treatments further optimize cassava derivatives like bioethanol and modified starch.

Large-scale automated plants improve production speed and consistency but require sustainable practices to mitigate environmental impact.

These innovations position cassava as a key global agricultural commodity.

Key Processes Include:

- Harvesting: The modern way of harvesting cassava involves the use of machinery and technology to streamline the process and ensure consistent product quality.

- Mechanized Peeling: The modern way of peeling cassava involves using machines to ensure efficient and effective peeling. Efficiently removes cassava skin, reducing waste, labor, and ensuring consistent removal of toxins for safer processing.

- Chipping: Slices cassava into uniform pieces for consistent drying and milling, ensuring better quality flour and starch production.

- Advanced Milling: Uses sophisticated machines to grind cassava into finer particles, producing high-quality starch and flour for multiple industries.

- Industrial Drying: Controlled drying processes reduce moisture content, extending shelf life and ensuring stability and quality of cassava products.

- Fermentation: Beneficial bacteria break down starches, improving flavor, nutritional value, and digestibility, and making products like gari gluten-free.

- Starch Extraction: Uses centrifuges to separate starch from cassava pulp, increasing purity and yield for use in various industries.

- Chemical Processing: Enzymatic treatments enhance cassava for industrial applications, turning it into bio-based products for sustainable alternatives.

- Automated Processing Plants: Streamlines large-scale production using robotics and software to improve efficiency, consistency, and quality, and reduce labor costs.

Related: Top 5 Cassava Processing Equipment for Small Business

Traditional vs Modern Cassava Processing Methods: A Comparative Analysis

Cassava processing has undergone remarkable changes over time, leading to two main approaches: traditional and modern.

Both methods serve the same purpose of transforming cassava into edible products, but they differ significantly in how they achieve this goal.

Related: How the cassava presser fits into the full processing line

Traditional Cassava Processing Methods

Traditional processing methods are deeply rooted in the culture and customs of communities where cassava is a key food source.

These practices have been passed down through generations, and they rely on manual labor. Common techniques include peeling, grating, fermenting, and sun-drying.

While traditional methods preserve local customs and engage the community, they are time-consuming and labor-intensive.

The final product’s quality can vary depending on individual skills and environmental factors.

As a result, production efficiency is often low, making it difficult to scale up to meet growing demand.

Modern Cassava Processing Methods

Modern processing, on the other hand, integrates advanced technologies and equipment to streamline the process.

Automated peeling, mechanical grating, and scientific fermentation processes have replaced many of the manual steps.

This approach allows cassava to be processed quickly and in larger volumes, meeting the increasing demand for cassava-based products like flour and starch.

With modern techniques, the entire process becomes more efficient, and resource use is optimized, reducing waste.

Additionally, modern systems emphasize food safety and hygiene, providing controlled environments that ensure high-quality products that meet international standards.

More on modern methods of processing cassava here.

The Role of Traditional Processing Methods in Modern Times

Despite the advantages of modern processing, traditional methods hold cultural value.

For many communities, these practices are an important part of their identity and heritage.

The desire to preserve these customs remains strong, even as modern technologies are adopted.

This has led to discussions on how to blend traditional and modern techniques.

A hybrid model that combines the efficiency of modern methods with the cultural wisdom of traditional practices could create a sustainable and respectful approach to cassava processing.

This model would not only increase production but also honor the rich cultural legacy associated with cassava.

Related: Best Manufacturers of Cassava Processing Equipment

Overview of Cassava Processing Methods for Different End Products

Understanding how cassava is processed helps optimize its use and meet the needs of various consumers.

Each manioc end product, from cassava starch to tapioca pearls, requires specific processing methods to ensure high quality and efficiency.

Cassava Starch and Tapioca Starch

Cassava starch is extracted using a wet milling process. First, the cassava roots are soaked in water to soften the skin, making peeling easier.

After peeling, the roots are ground into a slurry.

The slurry is then filtered to separate the starch from the fibrous material.

The resulting starch is dried into a fine powder, widely used as a thickener and stabilizer in the food industry. Here is an in-depth article on tapioca starch.

Cassava Flour

Cassava flour is made by peeling, drying, and grinding the cassava roots.

Once dried, the roots are processed into a fine flour that serves as a gluten-free alternative to wheat flour.

This flour is increasingly popular for baking and cooking, especially for those following gluten-free diets or looking for a healthier option. Here is a dedicated article on cassava flour.

Garri

Garri is made through a fermentation and roasting process. The cassava roots are grated, fermented for about 24 hours, and then roasted on a griddle.

The result is a granular product that can be consumed as is or used in various dishes, providing a staple food source in many African communities.

Fufu

Fufu is prepared by boiling and pounding the cassava roots until they reach a dough-like consistency.

This product is widely enjoyed in West Africa and is often served with soups or stews.

The process of pounding the boiled cassava gives fufu its signature texture and makes it a beloved part of the region’s cuisine. See the dedicated article on fufu and how it is made.

Tapioca Pearls

Tapioca pearls are made from cassava starch, which is shaped into small granules and cooked.

These chewy pearls are a common ingredient in desserts and beverages, such as bubble tea.

They add a unique texture and are enjoyed in various culinary applications. See more on tapioca pearls.

Cassava Chips

Cassava can also be processed into crispy chips. The roots are sliced thinly, fried or baked, and then salted or seasoned for a crunchy snack.

Cassava chips are a popular alternative to potato chips and offer a unique taste and texture. More on cassava chips.

Cassava Porridge

Cassava porridge is made by boiling grated cassava and then simmering it with water or milk, sugar, and spices.

This dish is common in parts of Africa and Asia and is a nutritious and satisfying breakfast or snack option.

Cassava Beer

In some regions, cassava is used to produce alcoholic beverages. The roots are fermented and processed to make a traditional beer or liquor.

Cassava beer is often brewed in local communities and has a unique flavor profile.

Cassava Sweets and Confectioneries

Cassava can also be transformed into sweets, such as cassava cakes, puddings, and other confections.

The roots are processed and mixed with sugar, flavorings, and sometimes other ingredients like coconut or chocolate to create a range of desserts.

Biofuel from Cassava

While less common, cassava is sometimes used in the production of biofuels.

The starch in cassava can be converted into ethanol, which can be used as an alternative fuel source.

This application has gained interest in areas focusing on renewable energy. More on cassava biofuel here.

Cassava Animal Feed

The by-products of cassava processing, such as the peel and fibrous material, can be used as animal feed.

These by-products are rich in nutrients and can be processed into feed for livestock, contributing to the agricultural economy. See a dedicated article on cassava animal feed.

Cassava Bread

Cassava bread is made by combining cassava flour or starch with other ingredients like water, sugar, and sometimes coconut to form dough, which is then baked.

It’s a gluten-free bread alternative and has gained popularity in regions where gluten-free diets are common.

The bread is often softer and denser compared to regular bread, with a slightly sweet flavor.

Textile Industry

Cassava starch is used in the textile industry primarily as a sizing agent. It helps in strengthening fibers and providing smoothness to fabric during the weaving process.

Its natural properties make it a preferred option for enhancing fabric texture and durability, offering an eco-friendly alternative to synthetic chemicals.

This use supports sustainability in textile production.

Cassava in the Paper Industry

In the paper industry, cassava starch is used as a binder and coating agent.

It helps improve the strength, smoothness, and printability of paper products.

The starch’s natural origin makes it a sustainable choice for paper manufacturers, reducing the need for synthetic additives.

As demand for eco-friendly products grows, cassava starch plays a key role in promoting green paper production.

Related: Cassava Grating Machine Guide

Quality Control and Food Safety in Cassava Processing Methods

When processing cassava, ensuring quality control and food safety is critical.

To meet both regulatory standards and consumer expectations, it’s important to follow systems that minimize risks.

One widely used method is the Hazard Analysis and Critical Control Points (HACCP) system, which helps identify potential hazards during food production.

This approach is key to producing safe cassava products. Here is how:

Monitoring and Managing Risks

HACCP focuses on monitoring key stages in cassava processing, including storage, washing, peeling, and cooking.

Each stage is an opportunity to identify hazards like microbial contamination or chemical residues.

For example, raw cassava contains cyanogenic glycosides, which can be harmful.

However, proper cooking can break down these toxins, making the product safe to consume.

By following specific guidelines, producers can reduce health risks and ensure a high-quality product.

Adhering to Safety Guidelines

Cassava processors must also comply with local and international safety standards.

The Food and Agriculture Organization (FAO) and the World Health Organization (WHO) offer valuable guidelines for food handling.

Best practices include maintaining cleanliness, using safe water, and training staff in proper food safety procedures.

These measures not only ensure safety but also enhance the reliability of the final products.

Building Consumer Trust

By maintaining strict quality control and following safety protocols, producers can build consumer trust.

This ensures that cassava-based products meet the required safety and quality standards, making them reliable for global markets.

Adhering to these practices benefits both producers and consumers, fostering a safer and more sustainable cassava industry.

Challenges in Cassava Processing

Cassava processing brings with it a number of challenges, especially due to natural toxins like cyanogenic glycosides and potential mycotoxin contamination.

When cassava is not processed properly, these toxins can release harmful cyanide, creating a health risk for consumers.

This affects the marketability of cassava products. Additionally, poor storage and handling can lead to mycotoxin contamination, further compromising the safety of the final products.

Here are the challenges facing cassava processing:

- Cyanogenic Glycosides: Cassava contains toxins that can release harmful cyanide if not processed properly, posing health risks to consumers.

- Mycotoxin Contamination: Poor storage and handling can lead to mycotoxins, which compromise the safety and quality of cassava products.

- Inconsistent Quality: Variations in root size and quality can result in uneven processing, affecting the end product’s consistency.

- Labor-Intensive Processing: Traditional cassava processing methods require significant manual labor, which can increase production costs and reduce efficiency.

- Limited Shelf Life: Cassava products are perishable, and improper storage or slow processing can lead to rapid spoilage and waste.

- Lack of Proper Infrastructure: Inadequate processing facilities and equipment in some regions hinder the efficiency and safety of cassava processing.

- Toxin Residues in Byproducts: Processing byproducts, if not properly treated, can contain harmful residues that affect overall product safety and quality.

- Environmental Impact: Traditional processing methods may involve unsustainable practices, contributing to environmental degradation, waste, and resource depletion.

- Health and Safety Risks for Workers: Inadequate protective measures during processing can expose workers to health risks, such as dust inhalation or toxic chemicals.

- Inconsistent Processing Techniques: Variations in processing methods across different regions can lead to discrepancies in product quality, limiting marketability.

Innovative Solutions in Cassava Processing

To overcome these challenges, the cassava industry is exploring new approaches.

One effective solution involves improving traditional methods like soaking and fermenting cassava roots.

Research shows that optimizing fermentation and combining it with controlled drying techniques can reduce the harmful cyanogenic glycosides in cassava, making it safer for consumers.

Technology’s Role in Cassava Processing

Technology is playing a major role in improving cassava processing. Tools like precision agriculture and smart monitoring systems help farmers manage crops more efficiently, reducing the risk of mycotoxins.

Meanwhile, new processing machines make it easier to extract starch and other valuable byproducts from cassava.

This boosts productivity, cuts down on waste, and leads to safer, higher-quality products.

Future Prospects for Cassava Processing

Cassava processing is evolving with new technologies and changing market demands.

As industries shift toward sustainability, cassava has the potential to become a key player in food production, biofuels, and industrial applications.

With its nutritional value and adaptability, it offers opportunities across multiple sectors.

Advanced Technologies in Cassava Processing

Innovation is shaping the future of cassava. Bioengineering and artificial intelligence are improving efficiency from cultivation to final production.

Precision agriculture helps farmers optimize yields, ensuring a steady supply of quality raw materials.

Modern processing equipment is also improving extraction methods, reducing waste, and increasing the usability of cassava in different industries.

Rising Demand for Gluten-Free and Alternative Flours

Health-conscious consumers are driving demand for gluten-free options, making cassava flour a popular choice.

Expanding product lines to include cassava-based snacks, fortified flours, and ready-to-use ingredients can open new markets.

Cassava starch is also gaining traction in industries like textiles and pharmaceuticals, offering even more growth potential.

Sustainability and Environmental Responsibility

Sustainable cassava processing is becoming a priority. Eco-friendly methods reduce waste and minimize environmental impact, making cassava products more attractive to consumers who care about sustainability.

Adopting cleaner processing techniques and responsible sourcing practices strengthens cassava’s position in global markets.

Cassava’s future is promising, with advancements in technology, expanding market opportunities, and a growing focus on sustainability.

As the industry evolves, staying ahead with innovation and responsible practices will ensure cassava remains a valuable resource for food, energy, and industry.

Frequently Asked Questions

Why does cassava need to be processed?

Processing eliminates toxins, extends shelf life, improves flavor, and enhances cassava’s commercial and industrial usability, ensuring safe consumption.

What are the main methods of cassava processing?

Peeling, drying, fermentation, milling, and industrial starch extraction transform cassava into safe, long-lasting, and high-value products.

How does cassava processing support the economy?

Cassava processing creates jobs, reduces food waste, boosts agricultural industries, and provides raw materials for food and industrial sectors.

What are the benefits of modern cassava processing?

Modern methods improve efficiency, consistency, and hygiene while enabling large-scale production and reducing environmental impact.

Can cassava processing be sustainable?

Yes, sustainable practices include waste reduction, eco-friendly drying methods, and using cassava by-products for animal feed and biofuel.

What are the main challenges in cassava processing?

Cassava processing faces several challenges, including toxin removal, mycotoxin contamination, inconsistent quality, labor-intensive methods, limited shelf life, inadequate infrastructure, and environmental concerns.

Addressing these issues requires improved processing techniques, better storage, and technological innovations.

Conclusion

Cassava processing is important for maximizing the crop’s potential, ensuring safety, and unlocking its vast economic and industrial applications.

Traditional methods, such as fermentation and sun-drying, preserve cultural practices and enhance flavor, while modern technologies improve efficiency, quality, and large-scale production.

By transforming cassava into flour, starch, chips, and bio-based products, processing minimizes waste, extends shelf life, and meets growing consumer demand.

Additionally, cassava plays a vital role in global industries, from food production to pharmaceuticals and biofuels.

Sustainable processing methods further enhance its environmental and economic benefits.

However, challenges such as toxin removal, mycotoxin contamination, inconsistent quality, labor-intensive methods, limited shelf life, inadequate infrastructure, and environmental concerns must be addressed to ensure safer and more efficient cassava processing.

Citations:

- https://www.ncbi.nlm.nih.gov/books/NBK234676

- https://www.juanmagsasaka.com/2020/12/cassava-production-harvest-and-post.html

- https://www.fao.org/fileadmin/user_upload/inpho/docs/Post_Harvest_Compendium_-_Cassava.pdf

- https://www.cassavaprocessing.com/Blog/three_reasons_of_investing_in_cassava_flour_processing_industry_268.html

- https://www.fao.org/4/y5548e/y5548e0d.htm

- https://www.arc.agric.za/arc-iic/Pages/Cassava.aspx

- Cassava Processing in Africa

Chimeremeze Emeh is a writer and researcher passionate about Africa’s most transformative root crop—cassava. Through his work at cassavavaluechain.com, he explores the entire cassava industry, from cultivation and processing to its diverse applications in food, health, and industrial use.

He also writes for palmoilpalm.com, where he shares his extensive experience and deep-rooted knowledge of palm oil, covering red palm oil, palm kernel oil, and refined products. His work there reflects his lifelong connection to agriculture and his commitment to promoting sustainable value chains in Africa.

Driven by curiosity and purpose, Chimeremeze aims to shed light on how cassava continues to empower communities, strengthen food systems, and link traditional farming wisdom with modern innovation.