From root to product, see how modern methods of processing cassava turn this tough crop into flour, starch, and snacks using efficient, clean, and scalable techniques that save time and boost yield.

If you’re in farming, food production, or just curious about how this root crop gets from field to table, you’ll want to know how modern cassava processing works.

These methods save time, improve output, and follow strict safety and quality rules.

Traditional techniques still matter in some areas, but machines and automation now do most of the heavy lifting.

Clean peeling, fast drying, even grating, and proper storage are no longer time-consuming tasks.

This change helps farmers and processors reduce waste, cut costs, and meet growing demand.

From small producers to large industries, modern cassava processing keeps things faster, safer, and more efficient.

Let’s break down what today’s cassava production really looks like and why it matters now more than ever.

If you are new to everything cassava, here is a good resource for you.

Benefits of Modern Methods of Processing Cassava

Modern cassava processing techniques improve efficiency, enhance product quality, reduce waste, and ensure food safety.

These innovations also support economic growth and environmental sustainability in cassava-producing regions.

Here are the benefits of investing in modern cassava processing methods.

- Improved Efficiency and Speed: Modern machinery automates peeling, grating, drying, and packaging processes, significantly reducing labor and processing time compared to traditional methods.

- Enhanced Product Quality and Consistency: Advanced techniques ensure uniform drying, controlled fermentation, and cleaner handling, resulting in higher-quality cassava products like flour, starch, and gari.

- Increased Shelf Life and Safety: Modern methods more effectively reduce moisture content and prevent contamination, extending the shelf life and ensuring the safety of cassava-based products.

- Better Utilization of By-products: Innovative processing allows for the extraction and use of cassava by-products such as animal feed, bioethanol, and biogas, minimizing waste.

- Boosted Economic Opportunities: Modern processing enables larger-scale production, value addition, and access to broader markets, thereby creating jobs and boosting income for farmers and processors.

Harvesting and Initial Handling

If you grow cassava or work with it after harvest, what you do in the first few hours matters.

Cassava roots start to spoil quickly, so fast and careful handling is key. You can use mechanical harvesters instead of digging by hand and risking damage.

They save time and protect the roots from cuts and bruises. After harvesting, move the roots in clean, ventilated containers to prevent moisture buildup and reduce spoilage.

Stack them well during transport to avoid impact damage. If you have access to mobile processing units, use them near the farm.

They let you start peeling and chopping right away. The sooner you handle cassava properly, the better your yield, shelf life, and market quality.

Related Posts

Local and Modern Cassava Processing Equipment

Traditional Methods of Processing Cassava

Four Methods of Making Cassava Flour

Grated Cassava: How to Grate and Freeze

Tapioca Guide: Everything to Know

What is Cassava Ethanol? Production Process

Cassava Production Tools For Small-Scale Setups

Cleaning and Peeling: A Modern Approach

When it comes to cleaning and peeling cassava, getting it right is key to maintaining quality and safety.

Traditional methods can leave behind soil and contaminants, affecting the final product.

With mechanized washing systems, high-pressure water jets and brushes clean cassava more effectively, ensuring a hygienic start to processing.

This upgrade removes soil and harmful substances, keeping your product safe for consumption.

For peeling, automated machines save time and reduce the need for skilled labor. These systems peel cassava evenly, improving consistency and quality.

Uniform peeling means better taste and texture. Mechanized systems also reduce the risk of contamination since they meet hygiene standards and can be easily sanitized.

By integrating modern technology, you improve efficiency, safety, and overall product quality.

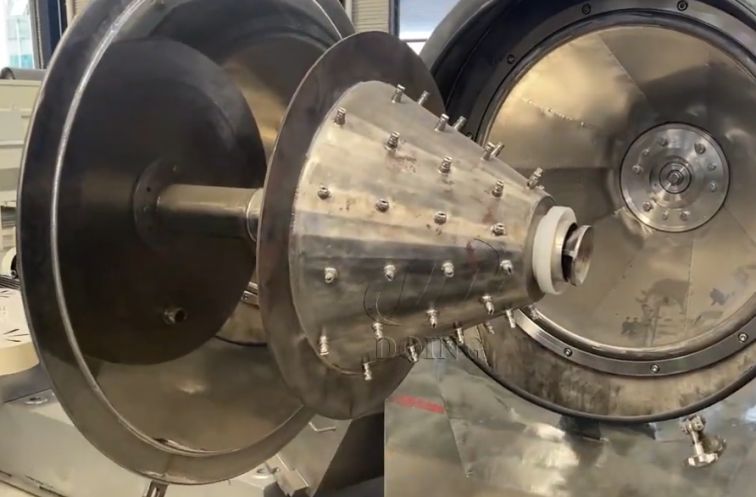

Grating and Crushing Cassava: Modern Methods for Better Efficiency

When it comes to grating and crushing cassava, technology has made a huge impact on how it’s done.

High-capacity graters and crushers are now the standard in modern cassava processing.

These machines allow for faster processing with minimal manual labor, improving overall productivity.

Modern graters use durable stainless steel blades that can handle large quantities of cassava quickly.

This helps meet the demand for continuous production, reducing bottlenecks.

Similarly, crushing systems with advanced designs provide a steady flow of cassava, ensuring consistency in texture and quality.

Variable speed controls and intelligent monitoring make these machines adaptable to different types of cassava.

The result? Less waste, better resource management, and more efficient production.

As the need for cassava grows, these advancements keep processing operations running smoothly and sustainably.

Modern Fermentation in Cassava Processing

Fermentation is an important step in turning cassava into value-added products like garri and fufu.

When done right, it transforms the starches in cassava into simpler sugars and acids.

To make sure fermentation happens under the right conditions, modern fermentation tanks with temperature controls are used.

This helps create the perfect environment for microorganisms to work their magic and produce a consistent final product.

Using starter cultures in fermentation is a game-changer.

These cultures introduce specific microorganisms that help improve flavor, texture, and shelf life while reducing spoilage.

They also make fermentation more predictable by outcompeting unwanted bacteria.

If managed properly, fermentation can also add beneficial probiotics, making cassava-based products healthier.

On top of that, fermentation breaks down harmful compounds in cassava, boosting the availability of important vitamins and minerals.

For regions where cassava is a staple, this is a huge benefit for improving nutritional value.

With controlled fermentation, cassava products can meet safety standards while delivering high-quality, nutritious food.

Dewatering and Drying

Dewatering and drying are key steps in cassava processing, helping to preserve quality and nutritional value by removing excess moisture.

Modern dewatering methods like hydraulic presses and centrifuges efficiently extract water while maintaining nutrients.

After dewatering, drying extends shelf life. Solar dryers use natural energy, but rotary dryers offer more consistent results with controlled temperatures.

Flash drying quickly removes moisture while preserving quality.

The chosen method impacts the cassava’s flavor, texture, and shelf stability, making it crucial to select the right technique for optimal results, ensuring the cassava is both safe and marketable.

Milling and Sieving

Milling is an essential step in turning cassava into fine flour, which is widely used in food products. Two main techniques are used: hammer mills and disc mills.

Hammer mills crush cassava roots at high speeds using rotating hammers, breaking them into fine particles.

This method is fast and helps preserve the nutritional value of the cassava by minimizing heat during processing.

On the other hand, disc mills use two rotating discs to grind cassava, allowing for more control over the milling process.

This results in a consistent texture and customizable flour fineness to suit different culinary needs.

Both techniques are important in modern cassava processing, as they improve efficiency and ensure high-quality output for various applications.

Starch Separators

Starch separators are used to extract pure starch from cassava slurry.

After rasping or grating, the cassava pulp is mixed with water to create a starch-rich liquid.

A starch separator uses centrifugal force to separate starch granules from fiber, protein, and other residues.

This equipment ensures a high starch recovery rate while improving purity. By automating the separation process, you save time and reduce manual labor.

It also ensures consistent product quality, which is important for both food-grade and industrial starch applications.

Modern separators are energy-efficient and help maintain hygienic standards during processing.

Sifters and Sieves

Sifters and sieves help refine cassava flour or starch by removing unwanted particles like fiber, lumps, or foreign materials.

After drying, cassava products are passed through these screening systems to achieve uniform texture and particle size.

This step is important if you want to meet market standards and customer preferences for fine, clean products.

Automated sifters increase processing speed and reduce contamination risks.

You can adjust mesh sizes depending on your desired output.

Whether you’re producing cassava flour for food use or industrial-grade starch, this equipment helps ensure your product meets quality specifications before packaging or further use.

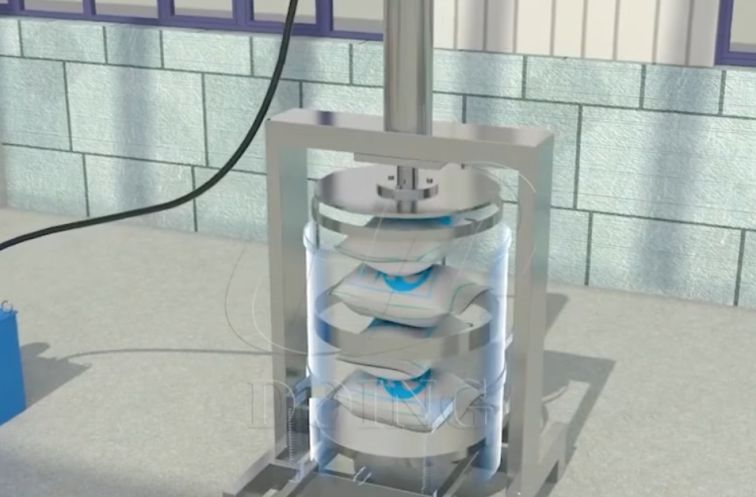

Cassava Presses (Hydraulic and Screw)

Cassava presses remove water from grated cassava mash before drying.

Hydraulic and screw presses are the most common types.

Hydraulic presses use pressure from fluid systems to squeeze out excess moisture, while screw presses apply continuous mechanical force through a rotating screw.

Both types reduce moisture content quickly, which shortens drying time and improves overall efficiency.

Using a press also helps reduce cyanide content by removing liquid that contains toxins.

These machines are built for heavy use and require minimal manual effort.

They’re ideal if you want faster processing, better starch yield, and improved product safety in cassava production.

Packaging and Storage

Effective packaging and storage are key to maintaining the quality and extending the shelf life of cassava.

Modern packaging techniques like vacuum packaging and modified atmosphere packaging (MAP) play a big role in this.

Vacuum packaging removes air before sealing, which slows the growth of microorganisms and reduces spoilage.

This helps keep cassava products fresh and nutritious for longer.

MAP, on the other hand, changes the gas composition around the product, reducing oxygen and increasing carbon dioxide and nitrogen.

This slows down spoilage and respiration, extending freshness.

Advanced storage solutions also help by controlling temperature and humidity, managing moisture, and preventing pest infestations, ensuring the cassava stays in top condition until it reaches the consumer.

Environmental and Safety Considerations in Cassava Processing

Modern cassava processing methods focus on improving efficiency while addressing key environmental and safety concerns.

These considerations are vital to ensuring the industry’s sustainability and responsible practices.

Waste Management

Cassava processing generates considerable waste, especially in the form of peels and effluent.

If not managed properly, this waste can harm the environment.

Innovative waste management solutions have emerged, such as recycling cassava peels for animal feed or converting them into biogas for energy production.

These approaches not only reduce environmental impact but also offer valuable byproducts that contribute to the circular economy.

Water Conservation

Traditional cassava processing consumes large amounts of water, putting pressure on local water resources, especially in drought-prone areas.

By adopting water-efficient technologies like closed-loop systems, processing facilities can significantly cut down on water usage.

These systems recycle water within the operation, reducing waste and helping minimize the ecological footprint of cassava processing.

Worker Safety

Worker safety is a top priority in modern cassava processing. Automation is key to improving safety by reducing the need for manual labor in hazardous areas.

Automated systems handle dangerous tasks, decreasing workers’ exposure to harmful substances such as cyanogenic glucosides found in cassava.

Though automation helps, ongoing training and adherence to safety protocols remain essential for maintaining a safe workplace.

Benefits of Modern Processing Methods in Cassava Production

Modern processing techniques have transformed the cassava industry, offering significant benefits for farmers and producers.

By adopting these methods, you can streamline your operations, boost productivity, and improve efficiency at every stage of production.

Increased Productivity and Profitability

Modern processing methods make it easier to boost yields per hectare. These techniques reduce the labor required, leading to a more efficient production process.

As a result, you’ll see an increase in output, which directly impacts your profitability.

This shift towards modern technology helps maximize your return on investment in cassava farming and processing.

Consistent Product Quality

One of the biggest challenges with traditional processing methods is the variation in product quality.

Modern technologies like mechanized processing and automated quality control eliminate these inconsistencies.

By ensuring a uniform standard in every batch, you improve your product’s marketability.

Consistent quality builds trust with consumers and businesses, which is key to maintaining loyalty and growing your customer base.

Export-Ready Products

With the global market expanding, modern processing methods also make your cassava products ready for export.

Meeting international standards is vital for accessing global markets.

Modern methods integrate hygienic practices and traceability systems that international buyers demand.

By aligning with these standards, you open doors to new market opportunities and potentially higher profit margins.

Frequently Asked Questions

Why is modern cassava processing better than traditional methods?

Modern methods are faster, cleaner, and safer. They reduce spoilage, boost output, and ensure consistent quality for food and industrial use.

How does modern technology improve cassava shelf life?

Efficient drying, controlled fermentation, and airtight packaging help extend shelf life by minimizing moisture, spoilage, and exposure to air or contaminants.

What makes cassava suitable for international export?

Hygienic processing, quality control, and traceability help cassava products meet strict international standards, making them export-ready and competitive globally.

Can small-scale farmers benefit from modern cassava processing?

Yes. Mobile units, shared equipment, and training help smallholders access modern tools, improving yield, reducing waste, and increasing profits.

Conclusion

Modern cassava processing methods are transforming how this resilient root crop is turned into high-value products like flour, starch, and snacks.

From mechanical harvesting and precise cleaning to advanced drying, milling, and fermentation, these innovations save time, reduce labor, and improve product quality.

Automation also minimizes waste, enhances safety, and opens opportunities for global trade.

Whether you’re a small-scale farmer or an industrial processor, adopting these scalable, efficient techniques helps you meet rising demand while staying competitive.

Plus, with eco-friendly solutions and better worker safety, the process becomes more sustainable.

In today’s market, modern cassava processing isn’t just an upgrade, it’s essential for quality, profitability, and long-term growth in the industry.

Chimeremeze Emeh is a writer and researcher passionate about Africa’s most transformative root crop—cassava. Through his work at cassavavaluechain.com, he explores the entire cassava industry, from cultivation and processing to its diverse applications in food, health, and industrial use.

He also writes for palmoilpalm.com, where he shares his extensive experience and deep-rooted knowledge of palm oil, covering red palm oil, palm kernel oil, and refined products. His work there reflects his lifelong connection to agriculture and his commitment to promoting sustainable value chains in Africa.

Driven by curiosity and purpose, Chimeremeze aims to shed light on how cassava continues to empower communities, strengthen food systems, and link traditional farming wisdom with modern innovation.